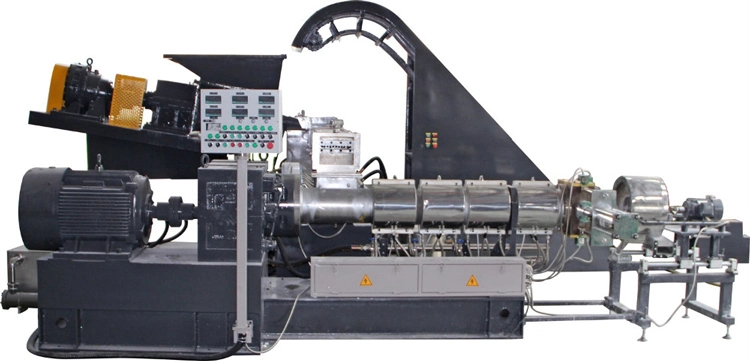

Plastic Extruder Machine for Make Plastic Pellets and Granules

Package Size 700.00cm * 200.00cm * 200.00cm Package Gross Weight 20000.000kg pvc compound extruder For pvc granules maki

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | TSE65 |

| Inverter | Inverter |

| Electromagnetic Heater | Electromagnetic Heater |

| Automation | Automatic |

| Computerized | Computerized |

| Customized | Customized |

| Certification | CE, ISO9001:2008 |

| Condition | New |

| Brand Name | Kairong |

| Color | Requiremet |

| Place of Origin | Nanjing,Jiangsu, China (Mainland) |

| Material | PP PE PVC Pet PC |

| Screw Design | Double |

| Voltage | 220V/380V |

| Capacity | 200-300kg/H |

| Keyword | Plastic Recycling Extruder |

| Transport Package | Wooden Case |

| Specification | TSE |

| Trademark | kairong |

| Origin | Nanjing, Jiangsu, China |

| HS Code | 84772090 |

| Production Capacity | 200-500kg/H |

Packaging & Delivery

Package Size 700.00cm * 200.00cm * 200.00cm Package Gross Weight 20000.000kgProduct Description

pvc compound extruderFor pvc granules making, Haisi Extrusion provides several PVC compound extruder to meet your various requirements.

Conical twin screw design PVC compound extruder

SJSZ conical twin screw extruder is mainly used for processing PVC products, such as PVC pipes, profiles, sheets, pellets and films.

SJSZ series pvc compound extruder have a high specific output rate because of screws' proper geometry, especially the longer pre-heating zone.

Technical parameters of PVC compound extruder

| Model | Screw diameter mm | Screw speed r/pm | Maximum extrusion rate kg/h | Main motor power kw | Heating power kw |

| SJSZ-55/110 | 55/110 | 40 | 180 | 30 | 20 |

| SJSZ-65/132 | 65/132 | 40 | 250 | 37 | 28 |

Two stage PVC compound extruderPVC very easily degrades at high temperatures (more than 170ºC). SP series tandem extruder is specially designed for PVC compounding.

1.The first stage is TSE twin screw extruder without die. Through the combination of barrel and screw, the extruder can exert its strong ability to make the thermo sensibility material like PVC melting, compounding, dispersing and decentralizing under the condition of no back pressure.

2.The second stage is SJ single screw extruder. Because of the lower rotating speed, it can complete melting, compounding lengthways and forming srands steadily, avioding over heating.

Technical parameters of SP series PVC compound extruder

| Model | Screw diameter | L/D | Rotary rate | Motor power | Output | |

| SP50-120 | TSE-50 | 50.5mm | 24-48 | 500r/min | 37-45kw | 150-300kg/h |

| SJ-120 | 120mm | 7-20 | 65-85r/min | 30-37kw | ||

| SP65-150 | TSE-65 | 62.4mm | 24-48 | 400-500r/min | 55-75kw | 200-500kg/h |

| SJ-150 | 150mm | 7-20 | 65-85r/min | 37-45kw | ||

| SP75-180 | TSE-75 | 71mm | 24-48 | 400-500r/min | 90-110kw | 300-600kg/h |

| SJ-180 | 180mm | 7-20 | 65-85r/min | 45-55kw | ||

| SP95-200 | TSE-95 | 93mm | 24-48 | 300r/min | 160-220kw | 500-1000kg/h |

| SJ-200 | 200mm | 7-20 | 85r/min | 90-110kw |

Processing of two stage air cooling PVC compound extruder

Features:

Combine the high speed and extensive mixing of processing and the low speed, low temperature, and low shear of single screw processing;

Ideal for compounding of heat and shear-sensitive materials.

Application:

PVC compounds for cable, shoe sole, transparent container, and medical applications.

Counter-rotating twin screw design PVC compound extruder

Our Counter-rotating Twin Screw Extruder is especially designed for PVC.

Possible materials : UPVC, CPVC, Medical grade PVC, Soft PVC, Rigid PVC, etc.

Features:

1. Unique screw design to achieve higher plasticizing and products quality

2. Gearbox of high torsion balance to realize stable running, low oil temperature available

3. H shape frame to decrease vibrating

4. PLC (Simatic Multi Panel) operation panel to ensure synchronization.

5. Energy conservation, easy to maintenance

Nanjing Haisi Extrusion is well experienced in twin screw extruder manufacturing. We supply high quality PVC compound extruder acorrding to your different requirements. Any interest please feel free to contact us!

Related Products

-

![PP PE EVA Pet Plastic Particles Color Sorter Machine for Separating Different Colored Plastic Granules]()

PP PE EVA Pet Plastic Particles Color Sorter Machine for Separating Different Colored Plastic Granules

-

![300kg/H Plastic Extruder Machine Plastic Granules Making Machine for Pelletizing]()

300kg/H Plastic Extruder Machine Plastic Granules Making Machine for Pelletizing

-

![Waste Plastic Crushed Washing Recycling Pelletizer, PP PE HDPE LDPE Llldpe Film Bag Granulating Melt Plastify Recycle Pelletizing Machine]()

Waste Plastic Crushed Washing Recycling Pelletizer, PP PE HDPE LDPE Llldpe Film Bag Granulating Melt Plastify Recycle Pelletizing Machine

-

![Single Shaft Shredder Recycling Machine for Electric Cable]()

Single Shaft Shredder Recycling Machine for Electric Cable