CaCO3 Filler Masterbatch Making Machine Double Stage Extruder Machinery Plastic Granule Machine

GS mach which is a manufacturing vendor, specializing in the twin screw extruder pelletizing line and spare parts, with

Send your inquiryDESCRIPTION

Basic Info.

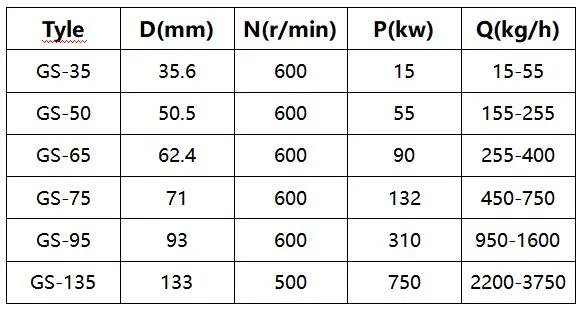

| Model NO. | GSD 75180 |

| Assembly Structure | Separate Type Extruder |

| Screw | Twin-Screw |

| Engagement System | Full Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| L/D | 40-52 |

| Machine Color | Customized |

| Engineer Experience | Yes |

| Video Guidance | Yes |

| Machine Design | Customized |

| Machine Type | Extrusion Type |

| Final Product | Filler Masterbatch / Biodegradable Granule |

| Inverter | Delta/ ABB |

| Motor | Siemens/ Wn |

| Raw Material | PP PE Calcium Carbonate / PLA Pabt /Corn Starch |

| Installation | Engineer Guidance |

| Name | Plastic Granule Making Machine |

| Custom | Yes |

| Screw Design | Twin Screw |

| Capacity | 100-900kg/H |

| Transport Package | Sea, Air and Land Transport |

| Specification | custom |

| Trademark | yes |

| Origin | China |

| HS Code | 802477 |

| Production Capacity | 1000kg/H |

Product Description

GS mach which is a manufacturing vendor, specializing in the twin screw extruder pelletizing line and spare parts, with high quality machine and competitive price.Here are some of our hot sale production lines for your kind reference

1. PLA PBAT+ corn starch biodegradable pellets making line2. PET bottle flakes recycling and pelletizing line3. EVA hot melt adhesive pelletizing line4. PP/PE/EVA etc.+CaCO3/Talc/TiO2 filler pelletizing line;5. PE/PP/ABS/AS/PA/EVA/PET etc. color/white/black masterbatch pelletizing line6. HDPE/LDPE/LLDPE/MDPE/EVA/PVC/PP etc. cable compounding line 7. TPU/TPE/TPR/TPV thermoplastic elastomer pelletizing line8. Glass/carbon fiber reinforced PA/PP/PBT/ABS/AS/PC/POM/PET etc.9. Various twin Screw elements, screw barrels, side feeders, heaters, etc.

For more details about our machine specification and configuration, pls kindly contact us:

Looking forward to hearing back from you. We are always glad to be at your service.

Twin Screw Extruder Compound Machine

Machine Type Choice:

Metering Feeder---Main Motor---Gear Box---Barrel---Screw Shaft---Soft Water Cooling System---Die Head--Cutting System

Introduction:

1. Twin-screw extruder with high-precision barrel and modular combination, lateral split, easy to change color

2. The segmented barrel body adopts the automatic control system of efficient heat exchange, non-solidification

3. Screw components can be freely combined according to technical requirements

4. Extruder twin screw, barrel and conveying parts are made of special alloy materials, making the machine more durable

5. Strong self-cleaning, strong shear force and high mixing efficiency

6. Gearbox is equipped with independent lubrication and cooling system, with high torque, low noise + 60DB, high wear resistance and long life

7. Twin-screw extruder adopts touch screen computer control system, safe operation

Advantage:

- Parallel co-rotating twin screw extruders have excellent mixing performance,good self cleaning performance and flexible modular configuration characteristics.

- The suitable for processing different types of material systems,and are extensively used in fields of polymer processing ,foodstuff processing and chemical products, especially for various high molecular materials.

- In most cases ,parallel co-rotating twin screw extruders are used as mixing equipment.In processing high molecular materials,the modification process and master batch preparation of Polyolefin material and engineering plastics require sufficient and intensive mixing,which differs depending on material systems, Excellent equipment performance,reasonable mixing process, advanced combination technique and rich processing experience are the key factors determining the success and efficiency of mixing.

Processing Raw Material:

Color Masterbatch:

PE,PP,PS,ABS,EVA,PET+Pigment and additives

Filling & Modification:PE,PP,PS,EVA+CaCO3,Talcum Powder,TiO2PP,PA6,PA66.ABS+Ferrous Powder,Magnetic Powder,Ceramic Powder

Blending&ModificationPP,PA,PE+EPDM;PE,PP,PS+SBS;PP+NBR;EVA+Silastic;

TPR compounds PP+PE;PBT+PET;PA,PC,CPE,TPU+ABSVarious Cable MaterialHDPE, LDPE, LLDPE, MDPE insulating bush, cable shieldPE Six-XLPE cable compounds,PE chemical crosslink cable compounds,

PE radiation crosslinking cable compounds,H-cable compounds PVC wire&cable compounds;HFFR,Polyolefine cable compoundsPowder CoatingPolyester coating,Polyurethane coating,epoxy resin coating,Propyl

Coating;Pcrylic coatingThermoplasticPhenolic aldehyde+glass-fiber,Urea-formaldehyde,Compounds epoxide powder caoating,Potting material,etc

Varions of Thermosets with serial production

Functional Masterbatch

CB masterbatch:PE,PP,PS ABS,EVA... +carbonFlame retardant masterbatch:PE,ABS,PA PBT...+flame retardant& additives Degradative masterbatch:PE,PS+Starch;PP+CaCO3,Talcum powderSafeguard function masrerbatch:Masterbatch of hest insulator...

Glass Fiber(carbon fiber, wood fiber)Reinfcrsersen

PE,ABS,AS,PBT,PET,PA,PC+Carbon fiberPP,ABS,AS,PBT,PET,PA,PC,PPO...+long glass fiber or short glass fiber

Different Types Cutting Systems:

- Water Strand Cutting System:water tank--dryer--pelletizer machine,

- Hot Air Cutting System:hot face die head cutting--blower--first cyclone--second cyclone--vibrate screen-silo

- Water Ring Cutting System:Water ring pelletizer--Centrifugal dehydrator--vibrating Screen--Cyclone Silo.

1. PLA PBAT+ corn starch biodegradable pellets making line

2. PET bottle flakes recycling and pelletizing line

3. EVA hot melt adhesive pelletizing line

4. PP/PE/EVA etc.+CaCO3/Talc/TiO2 filler pelletizing line;

5. PE/PP/ABS/AS/PA/EVA/PET etc. color/white/black masterbatch pelletizing line

6. HDPE/LDPE/LLDPE/MDPE/EVA/PVC/PP etc. cable compounding line

7. TPU/TPE/TPR/TPV thermoplastic elastomer pelletizing line

8. Glass/carbon fiber reinforced PA/PP/PBT/ABS/AS/PC/POM/PET etc.

9. Various twin Screw elements, screw barrels, side feeders, heaters, etc.

For more details about our machine specification and configuration, pls kindly contact us:

Looking forward to hearing back from you. We are always glad to be at your service.

Related Products