PVC XLPE Hffr Cable Insulation Material Plastic Cable Compounding Pelletizing Machine

Package Size 1000.00cm * 1000.00cm * 1000.00cm Package Gross Weight 1000.000kg XLPE Peroxide cross-linked Compounds: Pol

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | SKW-125 |

| Screw | Single-Screw |

| Inverter | Inverter |

| Electromagnetic Heater | Electromagnetic Heater |

| Automation | Automatic |

| Computerized | Computerized |

| Customized | Customized |

| Certification | CE, ISO9001:2008, QS |

| Condition | New |

| Electric Brands | Siemens / Schneider |

| Extruder Weight | 10000kg |

| Control | PLC + Touch Screen |

| Applications | All Kinds of Polymer Mixing |

| Capacity | 1000-1200kg/H |

| Transport Package | Pallet and Wooden Box |

| Trademark | XINDA |

| Origin | China |

| HS Code | 84772010 |

| Production Capacity | 200sets/Year |

Packaging & Delivery

Package Size 1000.00cm * 1000.00cm * 1000.00cm Package Gross Weight 1000.000kgProduct Description

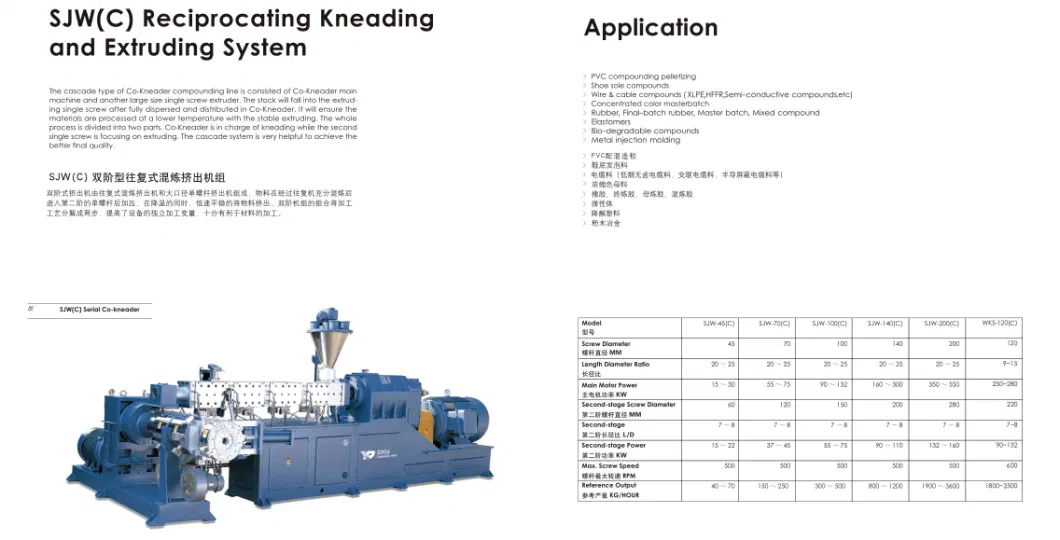

XLPE Peroxide cross-linked Compounds:| Model | SKW-100 | SKW-125 |

| Screw Diamenter | 105 | 125 |

| RPM | 600 | 600 |

| Reference Output | 500-800 | 800-1500 |

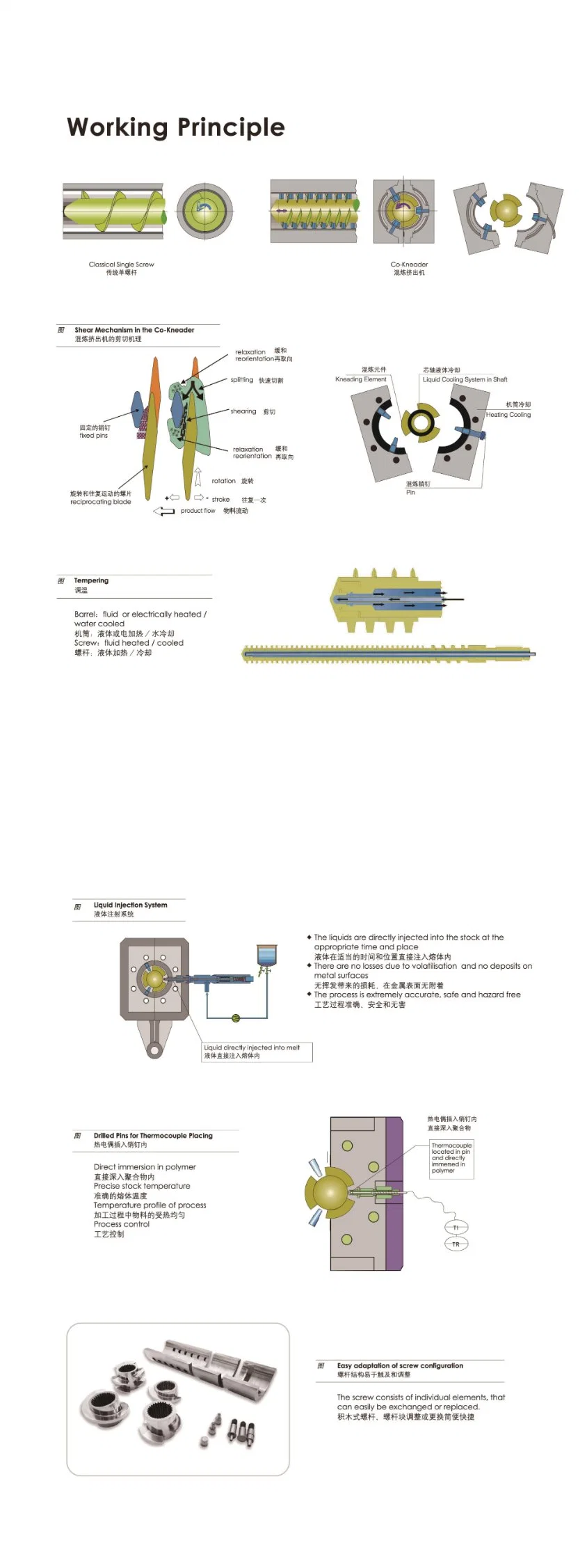

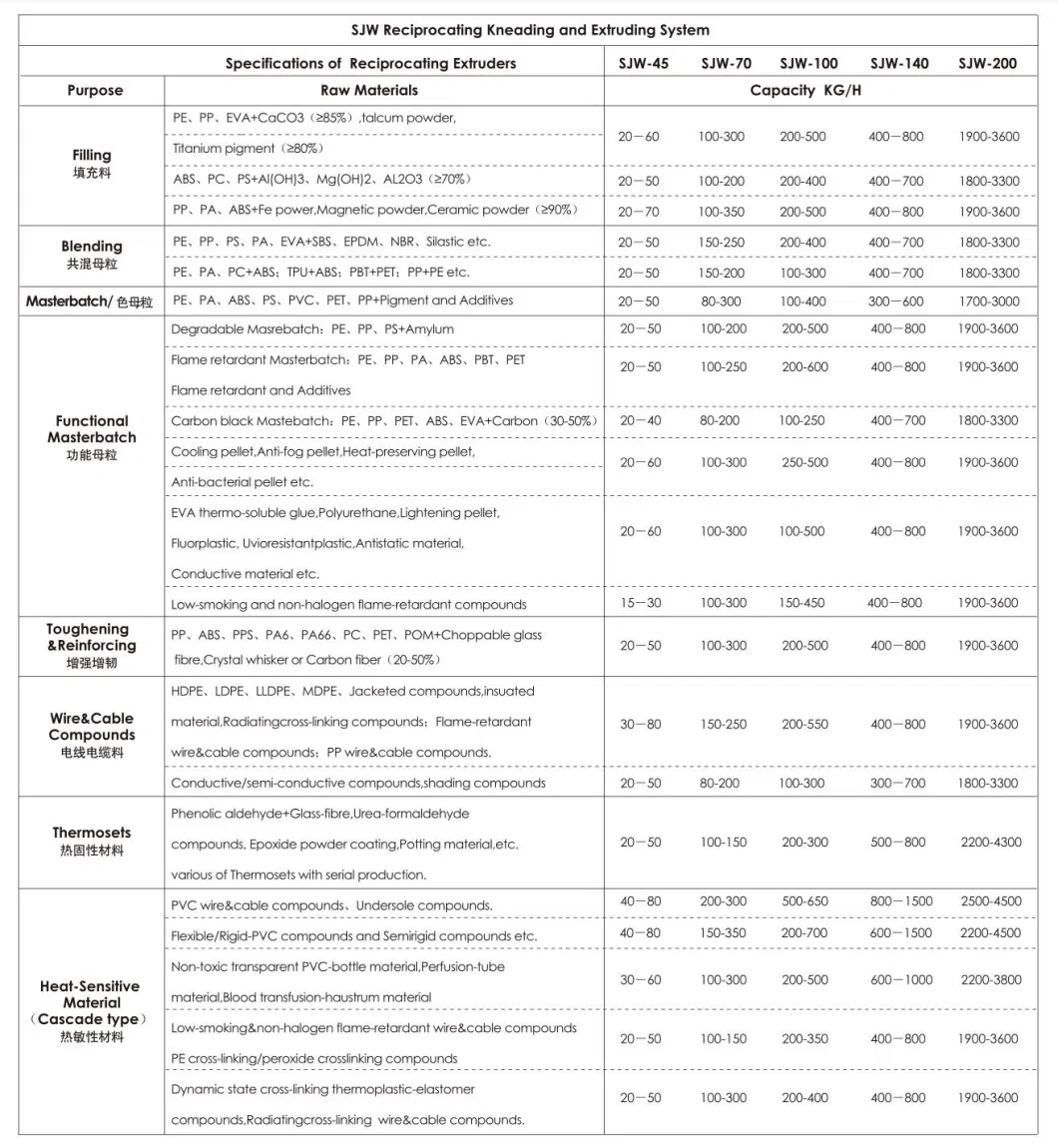

Polyethylenes (PE) have outstandingly good insulation properties. A temporary temperature rise, e.g. due to peak loading, can however cause a complete breakdown of PE cable insulation. The relatively low softening or melting point leads to thermo-mechanical failure or even dripping of the Insulation. Cross-linked polyethylene (PEX) is more thermosetting than thermoplastic. It can therefore be used at significantly higher operating temperatures, is mechanically stronger, more resistant to organic liquids, and often enables thinner wall thicknesses. Various cross-linking methods are used.The basic formula of peroxide cross-linked XLPE includes PE and peroxide. The peroxide liquid can be injected to co-kneader from hollow pins, which provides a free adaptation in barrel position and high outstanding mixing effect due to peroxide injected to polymer directly. The co-kneader has mild shearing to the whole process, and an easy switch-over is realized.

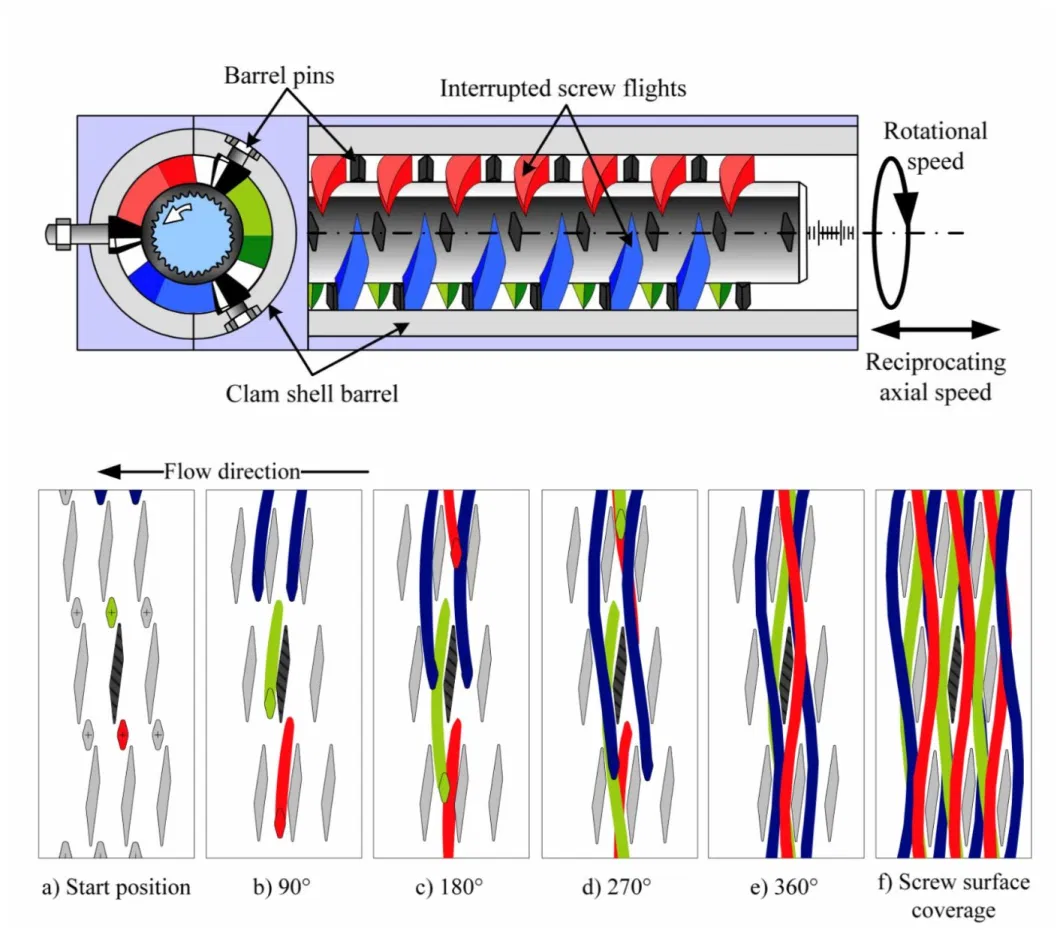

SJW XINDA Type Cascade Three Flights Co-Kneader Compound Extruder for XLPE Peroxide cross-linked CompoundsThe XINDA SJW Three flights compouding system,each spiral is broken by 3 gaps per revolution to locate the kneading flights, 3 rows of kneading pins,which are individually inserted in the barrel per 120 degree. The reciprocating wobble-box synchronizes the shaft rotation and oscillation so that each revolution of the screw is accompanied by one full stroke forward and backwards.This ensures optimal distributive and dispersive mixing with minimal energy consumption.

Advantages of the XINDA Co-kneaderThe Co-Kneader, a mild-shear rotating and reciprocating single-screw extruder, is designed for shear and temperature sensitive compounds. The flights on the screw are interrupted and interqct with three rows of stationarv kneadina pins located in the barrel wall. The interaction between the moving flights and the stationary pins provide dispersive and distributive mixing simultaneously. Axially opened split barrel guarantees ease of cleaning. Those splined, segmented screw elements and pins can be changed easily according to different processing techniques. In addition, some pins are hollow inside, thermocouples can be inserted to get the accu- rate temperature of the materials inside the barrels, so as to liquid additives injection. Different from other extruders, the kneading process is achieved radially and axially at the same time. All in all, Co-Kneader has outstanding kneading, mixing efficiency and high degree of self-wiping. It is the most suitable for compounding purposes.

XLPE peroxide cross-linked Compounds:

--For 35KVA cables

Details Images

Related Products

-

![Biodegradable PLA Plastics Granules Making Machine/Corn Starch Biodegradable Plastic Granule Making Machine Bio Plastic Machine]()

Biodegradable PLA Plastics Granules Making Machine/Corn Starch Biodegradable Plastic Granule Making Machine Bio Plastic Machine

-

![Waste PVC Pipe/PP Bag/Pet Bottle/PE Film Plastic Recycling Machine with Washing and Pelletizer/Extruder/Suqeezer/Granulator for Different Soft or Hard Materials]()

Waste PVC Pipe/PP Bag/Pet Bottle/PE Film Plastic Recycling Machine with Washing and Pelletizer/Extruder/Suqeezer/Granulator for Different Soft or Hard Materials

-

![Waste Pet/HDPE/LDPE/PP/PE Bottles Films Woven Bags Plastic Recycling Pelletizing/Granulator/Granulation/Flakes Scrap Crushing Washing/Squeezing Shredder Machine]()

Waste Pet/HDPE/LDPE/PP/PE Bottles Films Woven Bags Plastic Recycling Pelletizing/Granulator/Granulation/Flakes Scrap Crushing Washing/Squeezing Shredder Machine

-

![Plastic/LDPE/PE/PP/HDPE/LLDPE/BOPP/Film/Foil/Woven/Bags/Raffia/Centrifugal/Dewatering/Squeezing/Squeezer/Pelletizing/Pelletizer/Dryer/Machine]()

Plastic/LDPE/PE/PP/HDPE/LLDPE/BOPP/Film/Foil/Woven/Bags/Raffia/Centrifugal/Dewatering/Squeezing/Squeezer/Pelletizing/Pelletizer/Dryer/Machine